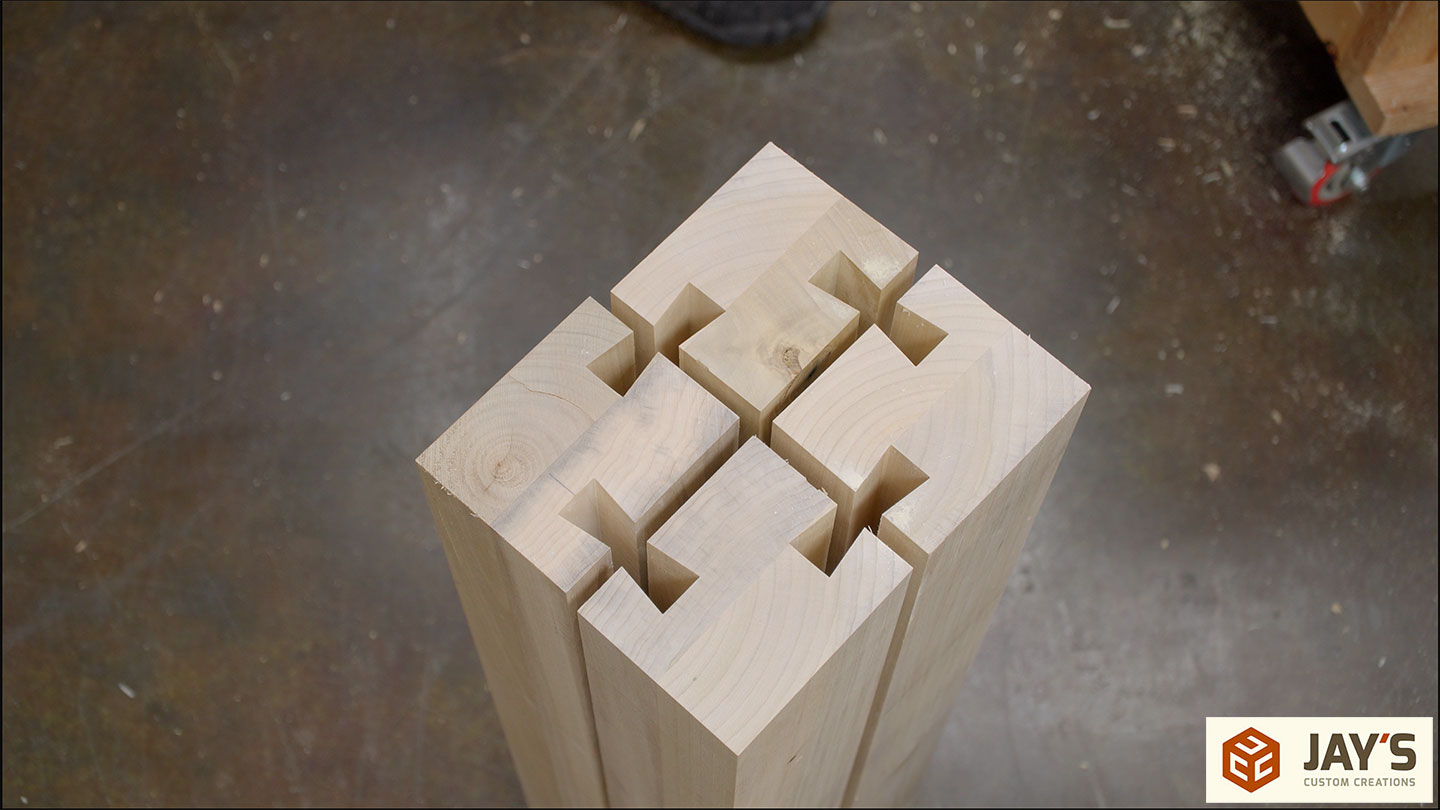

This week I’ve labored considerably with two gear utilized in woodworking and every so often in different fabrics like stone and plastic. One is definitively referred to as a rasp. Rasps are available quite a lot of widths, lengths and shapes. Hand-made rasps, referred to as hand stitched, will also be dear. My favourites up to now are the ones made by means of Auriou of France; the only I depend on maximum is the Cupboard rasp. This rasp is flat on one aspect and spherical at the reverse face. The top follows a steady boat form culminating in a delightful and helpful level and for many people those are probably the most helpful and sensible varieties irrespective of measurement. Mine is now 13 years outdated and it nonetheless cuts picket greater than smartly; fantastically is the phrase, actually. The smaller and narrower variations, perhaps 1/2″ to three/4″ vast and six-8″ lengthy, are superb for tighter, smaller paintings, shaping handles and such. Regardless of the dimensions, they’re fantastically balanced within the hand and lower fantastically successfully.

Prior to now, I normally prompt the 4-in-hand rasp, the kind utilized by farriers for trimming horse hooves after reshoeing horses. Those are a virtually first rate starter rasp for duties like shaping be that disposing of arduous corners to curves as in spoon and spatula making, reducing forums and so forth, however in recent times those rasps have are available with softer metal and fail to stay their edge for extraordinarily lengthy or are certainly are simply flat poorly made, a facsimile of what used to be the trade same old. When a rasp loses its reducing edges it turns into a bruising put in force bluntly attacking just right picket to go away it extra bruised than finely lower. I really like the type of ‘chew‘ and edge retention you get from the hand-stitched variations as with Auriou and Logier. My hope is that they’re going to proceed to live to tell the tale and stay elevating long run generations of professional rasp makers.

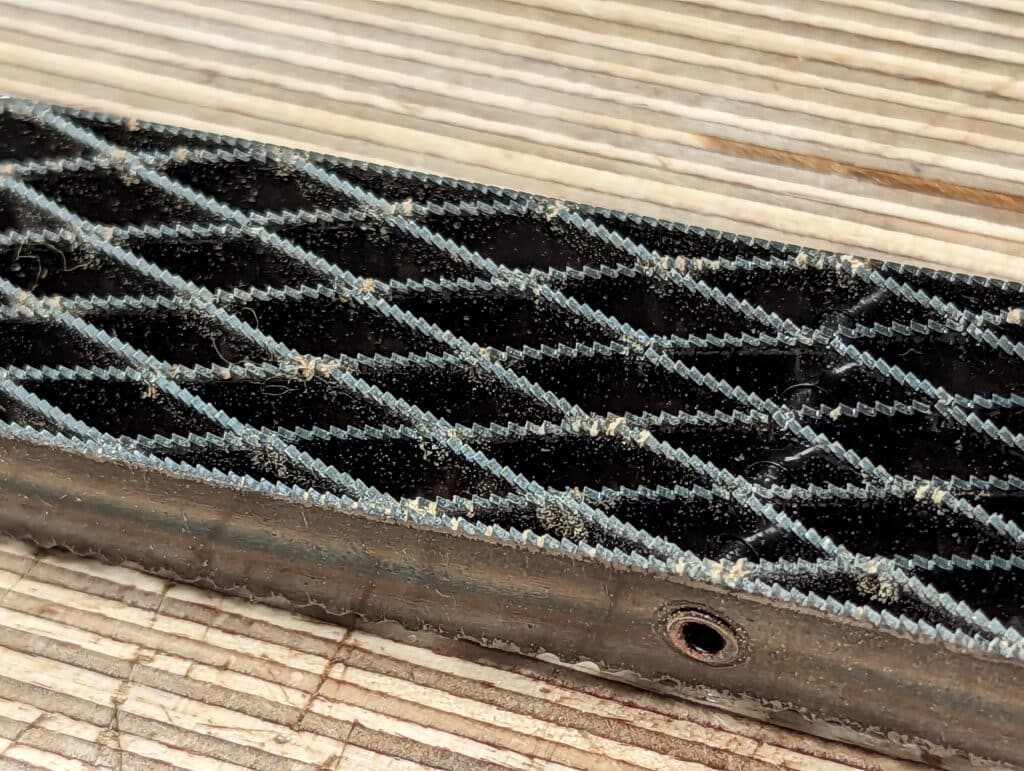

With reference to the 4-in-hand rasp: what’s in point of fact treasured is that you simply get 4 surfaces at the similar rasp. They’ve no take care of because the metal itself is the dangle you get and what you’ve is just right grip. The flat aspect will give you a part-period of exact rasp with the crucial layers of barbed sewing whilst the opposite part of the period is basically a report with finer reducing and smoothing skill. The opposite aspect is spherical and in this aspect, you once more get the rasp and report however within the spherical as a way to talk. It’s not that i am positive why the most productive makers of rasps have now not replicated a best-notch model of this device — a 12-14″ lengthy model with the boat-formed ends can be a wonderfully useful gizmo and most definitely a absolute best dealer for them. Nudge, nudge! Neatly inside their capability.

I take note the day I switched from the 4 in hand to the Auriou cupboard rasp; the 12″ #10 sewing. It used to be an evening and day enjoy but I additionally recall a 4-in-hand model that used to be in point of fact smartly made and intensely at hand all in one device. They impulsively declined in high quality and this used to be a right away results of less expensive imports robbing first rate makers by means of coming in at not up to part the cost with a glance-alike that fooled everyone into pondering they have been if truth be told getting one and the similar device. By the point everybody realised the adaptation, the great makers have been long past. That mentioned, 4-in-arms as distinct from farrier’s rasps do paintings and paintings smartly sufficient. They’re simply inferior to the top class variations. They are perfect for seeing if what you need to make use of rasps for shall be part of your long run; we ceaselessly use a transitional device like this ahead of we spend cash. on further particular ones.

It used to be sending a brand new woodworking maker to shop for a £140 rasp that brought about me to reconsider issues. The farrier model is indisputably nonetheless a just right have compatibility for beginning your children out or in case you are best making a couple of pieces requiring shaping by means of this technique of hand paintings. Somebody achieving into the longer term for lengthy-time period shaping will now know to imagine the hand-stitched variations and there are other makers available in the market who make really nice rasps, some from puts just like the Czech Republic are actually superb and are most often more cost effective too. I personal a pair and experience them.

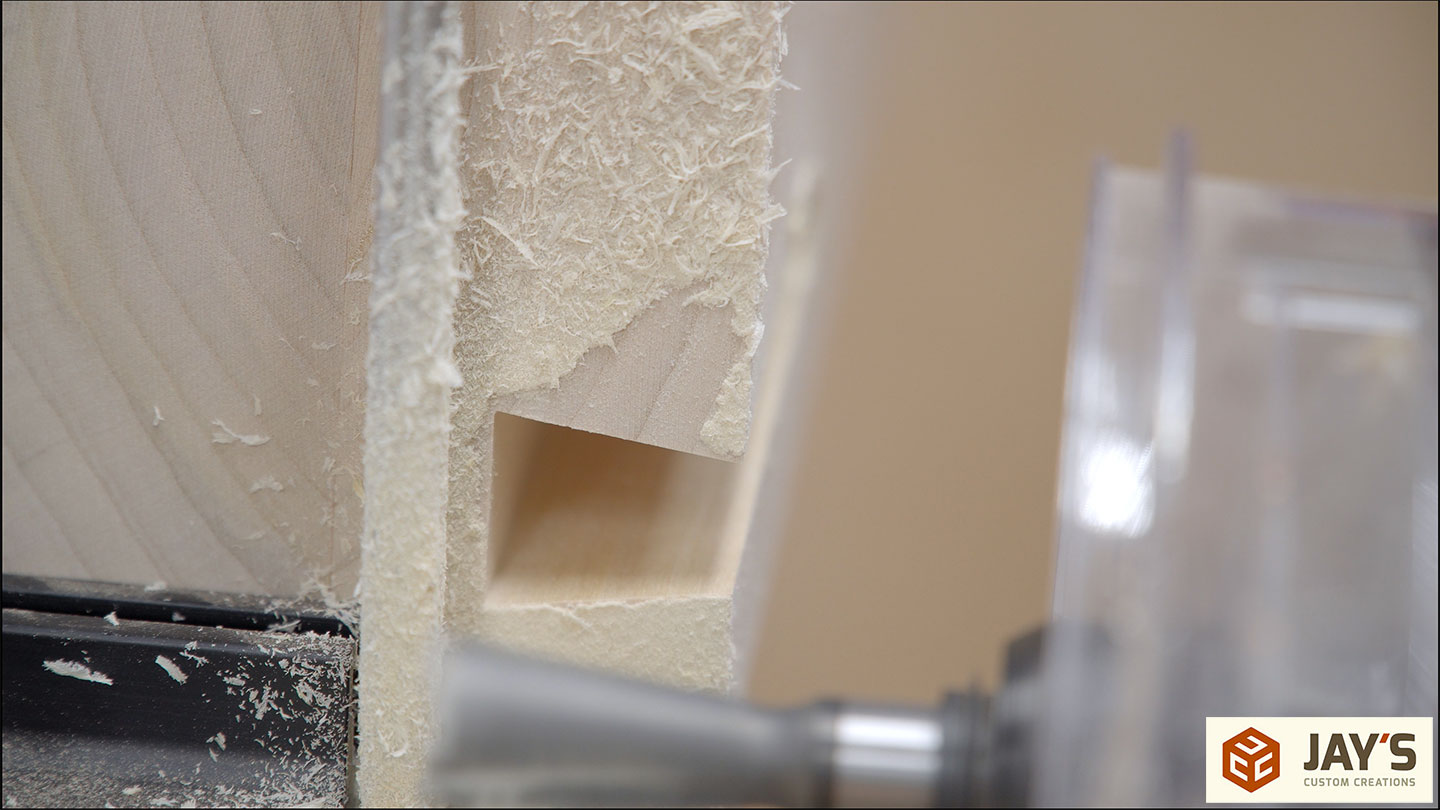

I purchased the Shinto noticed rasp as a substitute and feature examined it out for a just right period of time. I used one rather than my Cupboard Rasp to check out to figure out its longevity, capability and so forth. Its primary downfall is there is not any spherical face to it so it’s most commonly useable on flat and convex surfaces. Hollowing is out of the query. Its benefit is that it has each coarse and fantastic in one rasp. So far as worth is going, the cost has risen. It sort of feels it is going to value you someplace round £30-35. After a 12 months’s use, it has much less chew than the Auriou, to the purpose that I ordered its alternative. Evaluating the 13 years of use with the only 12 months of the Shinto leans against getting one-quarter the time I were given from my Auriou however my Auriou remains to be going and I choose the heft and really feel of it normally. So, my conclusion is that there actually is little distinction in total value aside from that we do have the spherical again to the Auriou and the coarse and fantastic faces of the Shinto.

For the primary phase, I will be able to are living with out the coarse aspect of the Shinto despite the fact that I will be able to see it being very at hand every now and then for starting up subject material in amount and temporarily. What I will not are living with out is the spherical again of the Auriou or different makers I’ve. A snappy turn of the wrist to maintain hollows and rounds similarly smartly with the similar fineness. However I’m content material now that I understand it isn’t an both-or. I will be able to prolong the lifetime of my Auriou and double and even triple its longevity by means of the usage of either side of the Shinto noticed rasp.

Conclusion: After lengthy-time period checking out, I experience proudly owning each the dearer rasps and the Shinto however the 4-in-hand- meets other standards. In case you get started with the 4-in-hand you’ll lose not anything beginning out and it’s just right for kids to paintings with. Then imagine the Shinto when you suppose you’ll don’t have any want for the spherical face of a correct rasp; this can be a stepping stone to proudly owning a top class rasp. There may be true pleasure in proudly owning an Auriou and maintaining it for absolute best paintings longer term. I believe for many woodworkers with restricted time of an afternoon per week on the bench that this may turn out to be an entire life device for them

Wiping varnish is merely any logo of oil-based alkyd (common) varnish or oil-based polyurethane varnish in any sheen (gloss or satin) thinned about part with mineral spirits (paint thinner).

Wiping varnish is merely any logo of oil-based alkyd (common) varnish or oil-based polyurethane varnish in any sheen (gloss or satin) thinned about part with mineral spirits (paint thinner).