Day 4 of the out of doors kitchen island construct begins with the door and drawer entrance meeting. I’m the usage of 1/2” plywood for the panels and will want to minimize a rabbet on every panel sooner than meeting.

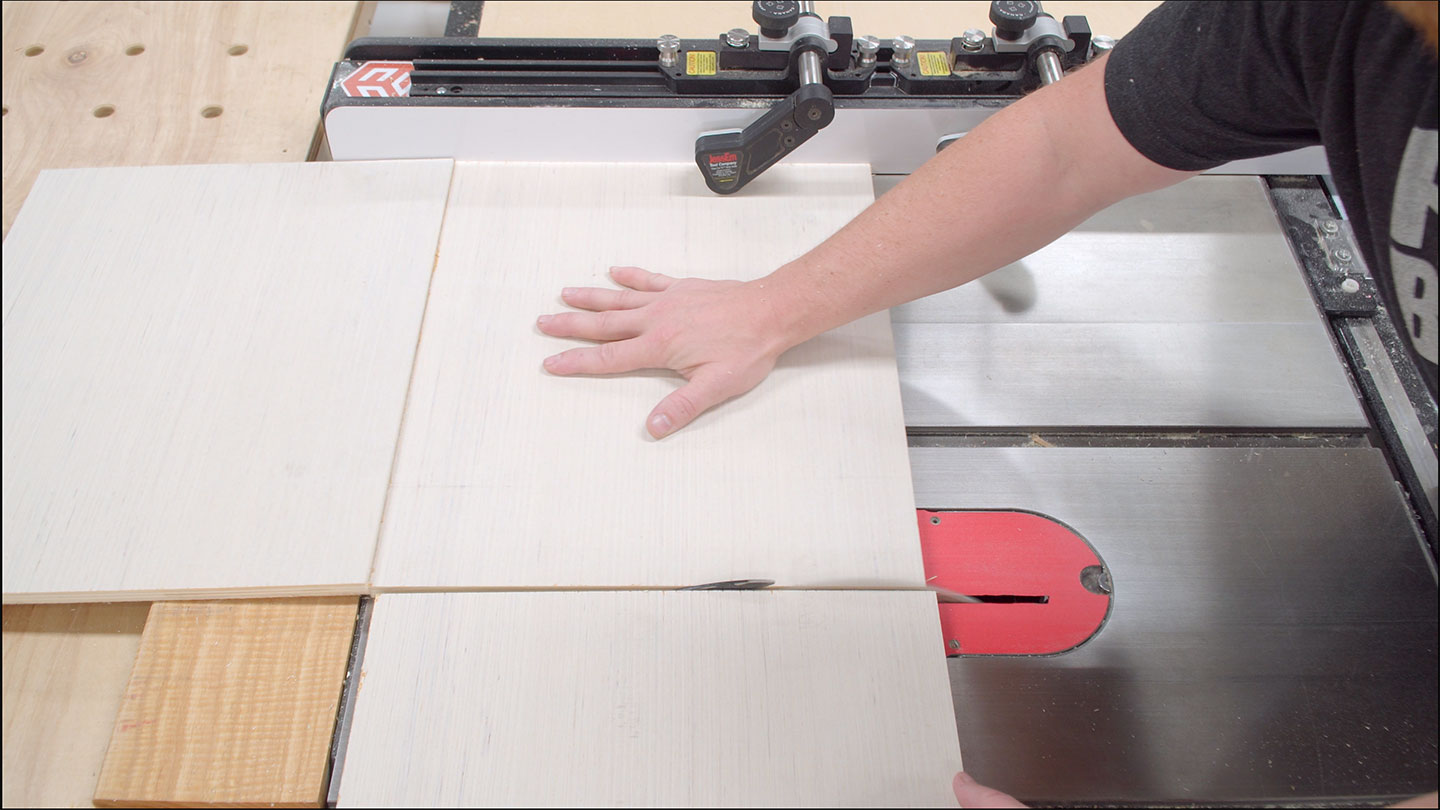

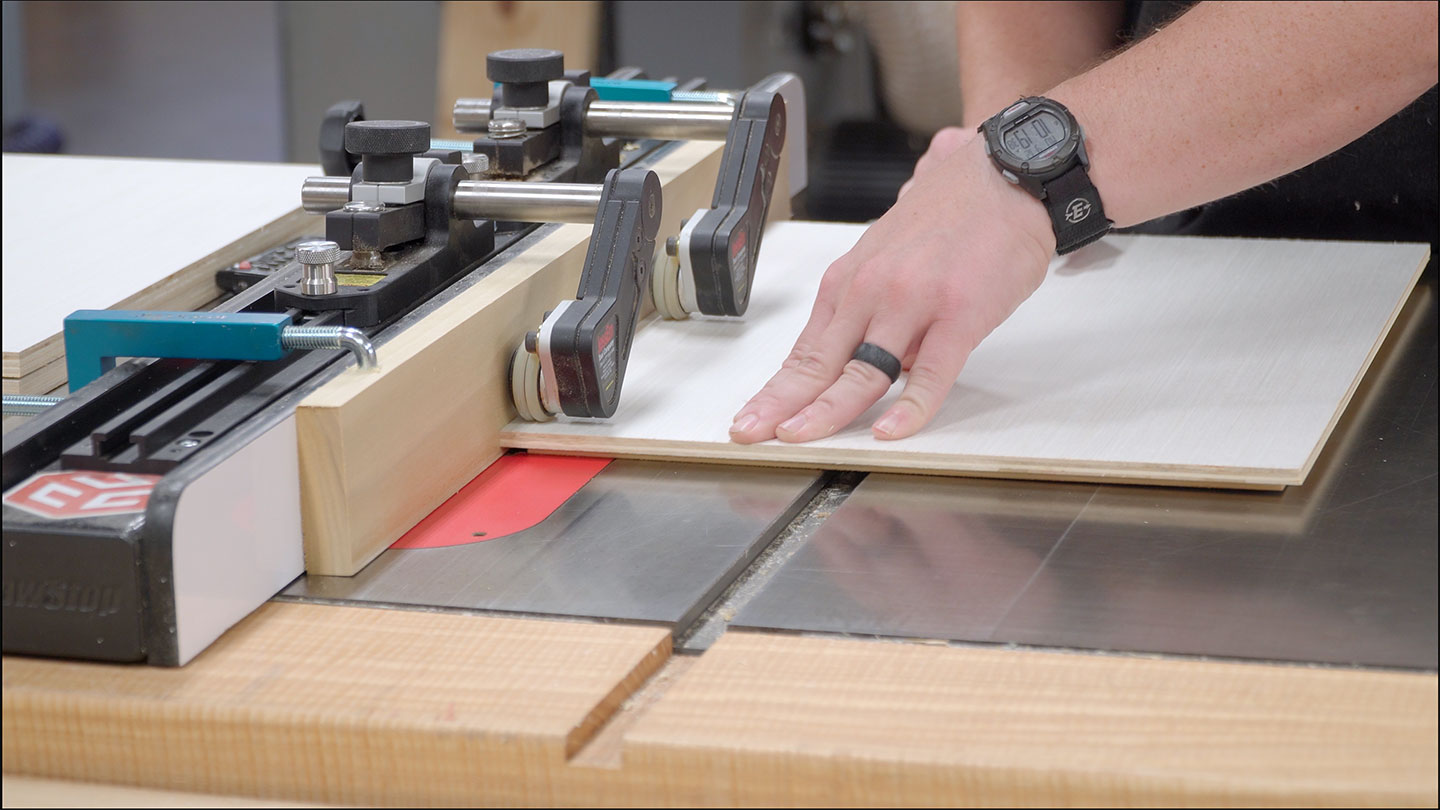

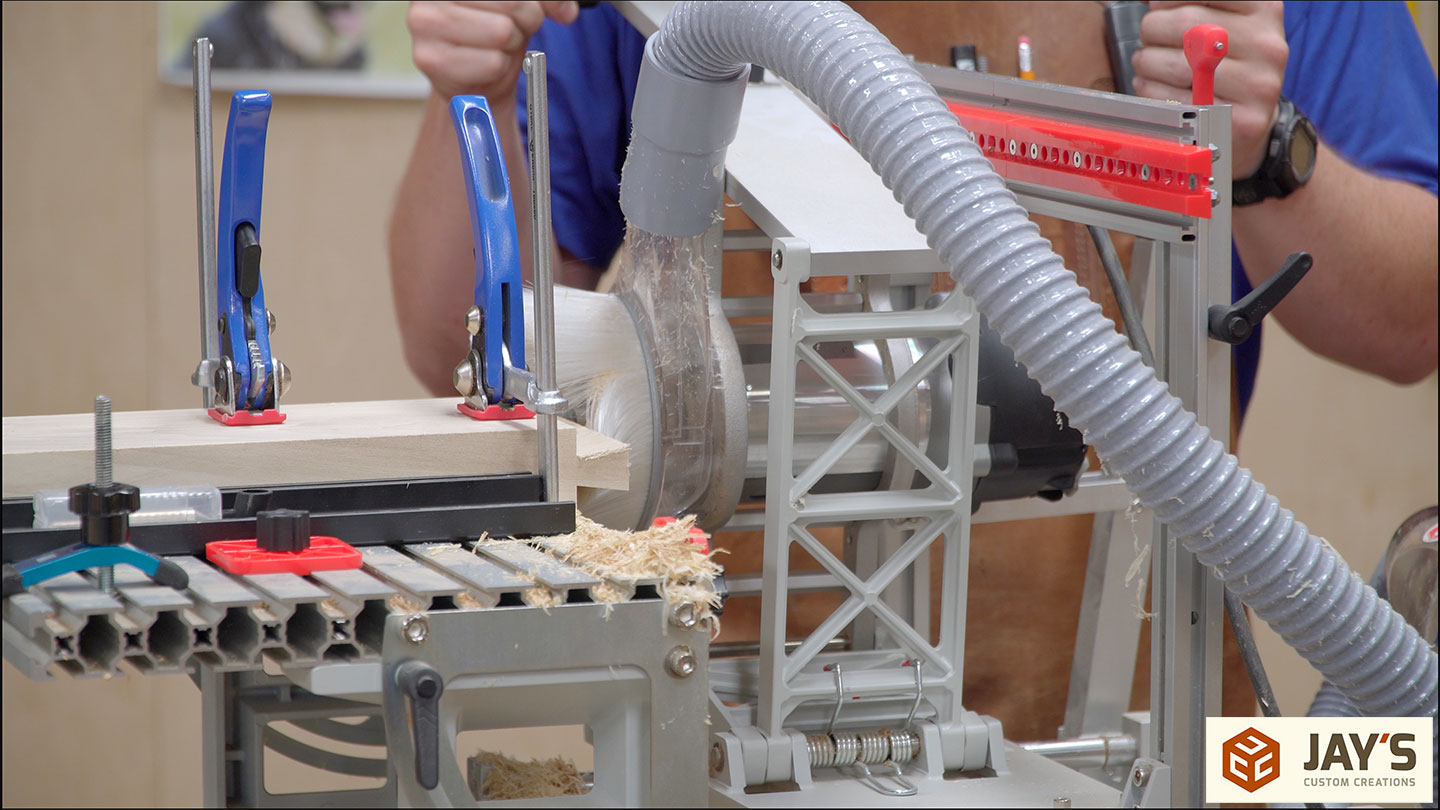

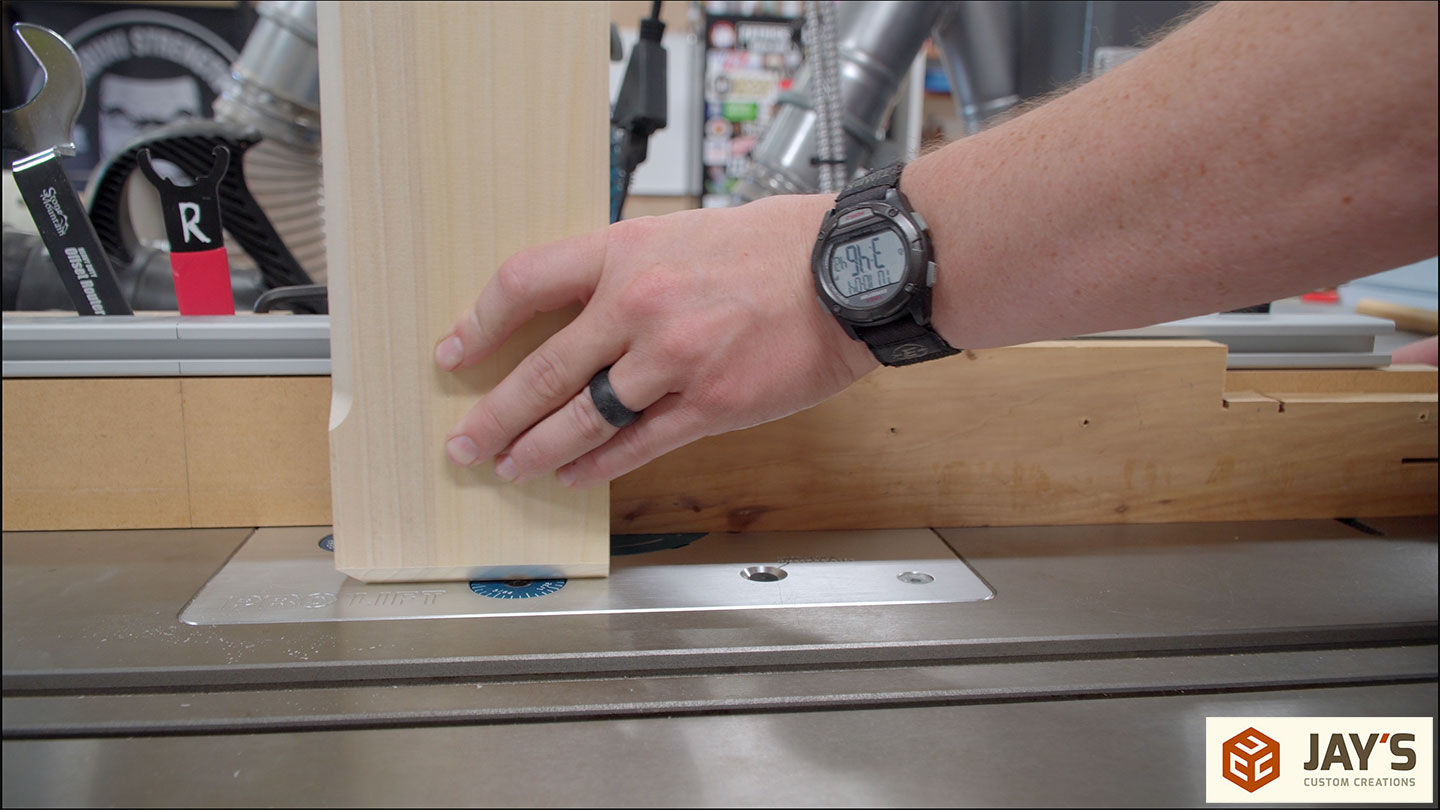

However first, a snappy notice on those JessEm curler guides. I really like them however haven’t been the usage of them in recent years because of laziness. Now and again I am getting in my very own approach. I’ve them, they paintings nice, and I must use them always. For those who’re no longer accustomed to them, they’ve a curler on a slight inward attitude towards the fence. The curler has grippy subject material to carry the workpiece and they just roll ahead. This very much reduces the chance for kickback. For smaller items not up to a few inches they only get in the way in which. On this case, they’re going to be useful.

When used, I’m straight away grateful that I’ve them. It’s peculiar how some pieces I’ll move out of my approach to make use of and others I’ll have lazy moments, even making an allowance for how handy they’re.

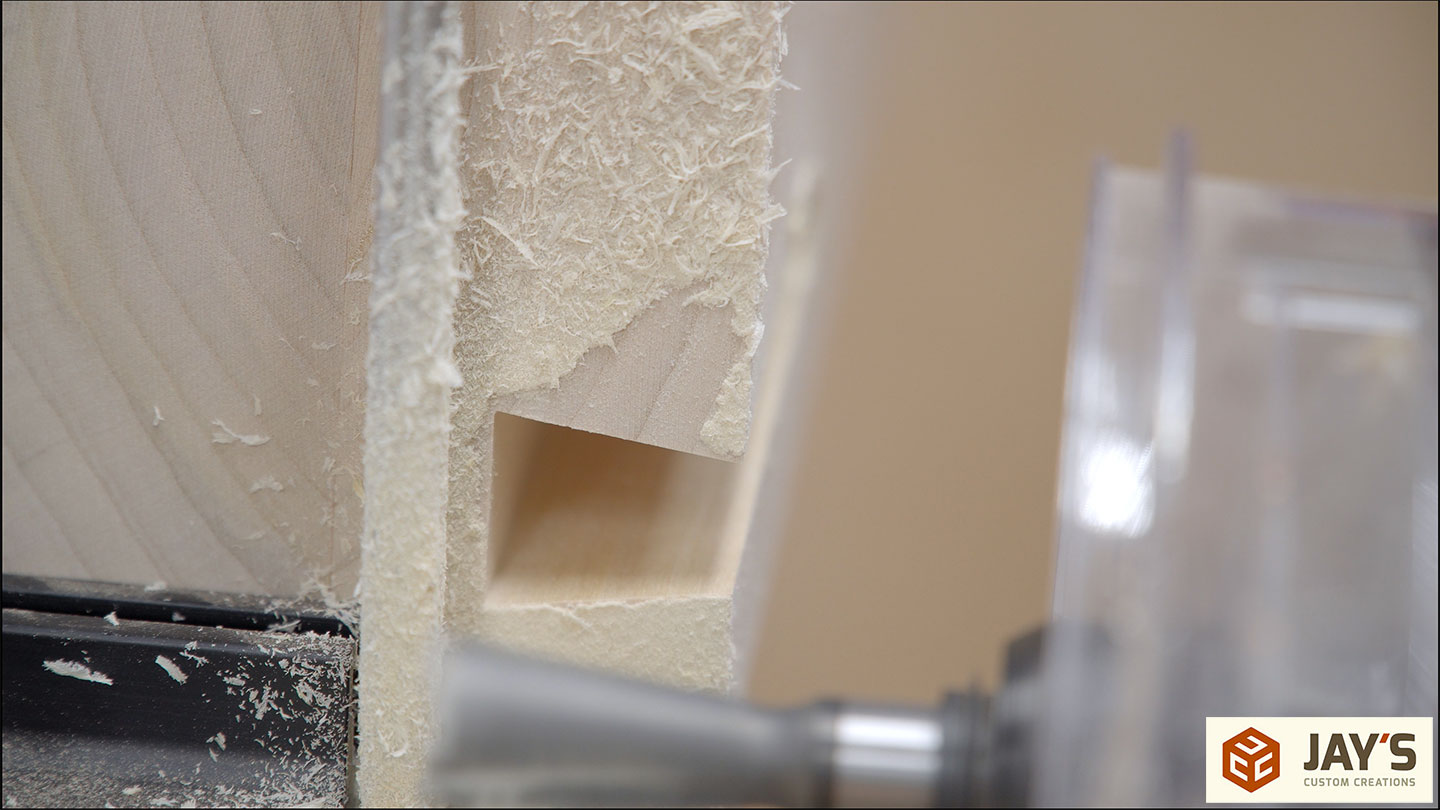

For the panel rabbets, I selected to make use of a dado stack within the desk noticed with a sacrificial fence. The sacrificial fence lets in the overall dado stack for use and buried within the fence. The fence place determines the width of the rabbet and the peak of the dado stack determines the intensity of the rabbet. As soon as dialed in, the interior face of the panel must be flush with the interior face of the door and drawer entrance frames. The entrance may have the standard 1/4” step not unusual in shaker cupboards.

Now the doorways and drawer fronts can also be assembled. Since the panel is an engineered panel, all of the panel can also be glued in position. Little need for a spread and contraction hole right here.

After you have the entire doorways and drawer fronts in clamps I notice why maximum cupboard stores choose to outsource their door introduction. Between milling the lumber, reducing the joiner, and assembling the doorways there may be a large number of time intake. It simply is sensible for a large number of cupboard stores to outsource this step.

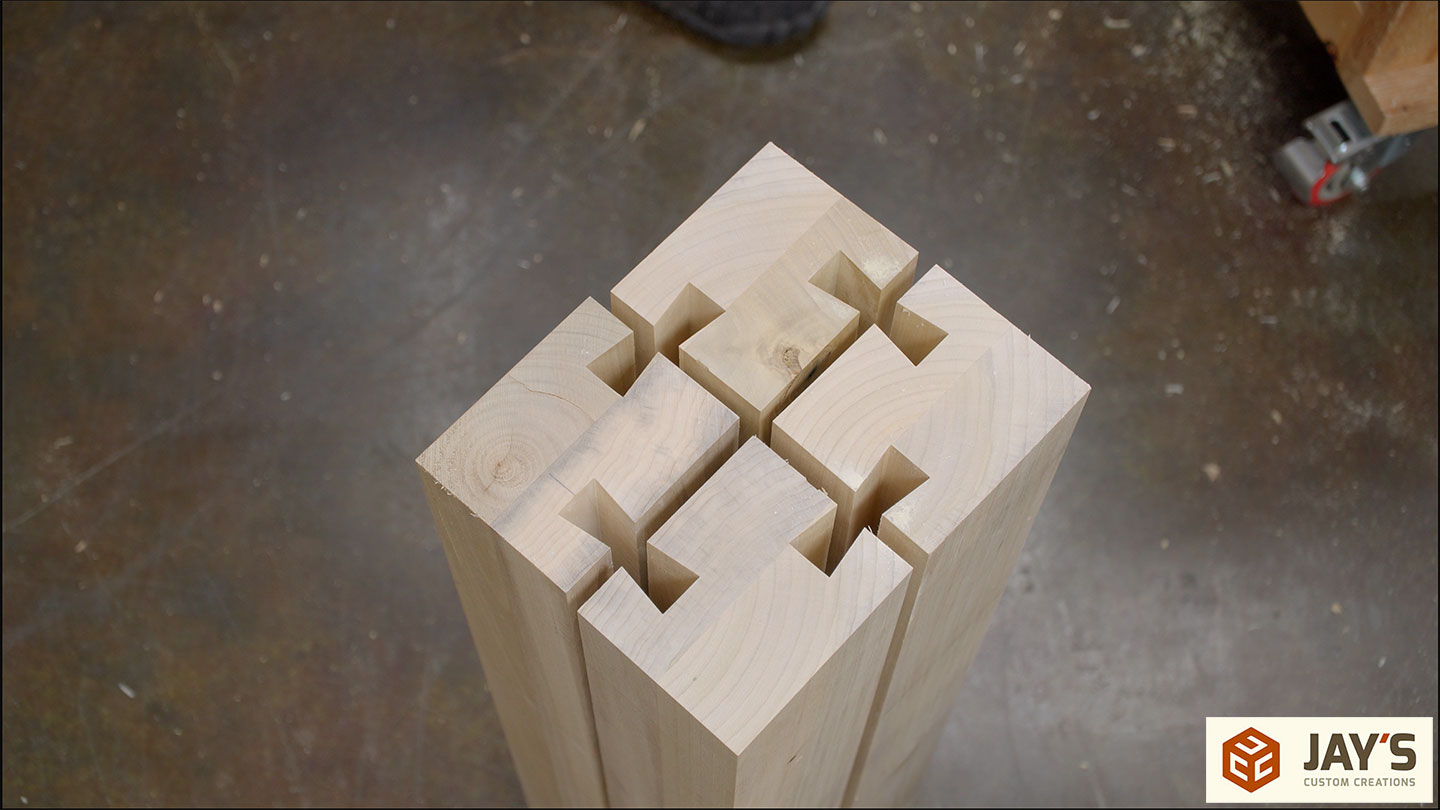

Whilst the doorways and drawer fronts are in clamps I converted to the legs. The 4 nook legs shall be sq. and the 3 inside legs shall be oblong.

The everyday milling technique of jointer > planer > miter noticed > desk noticed is adopted.

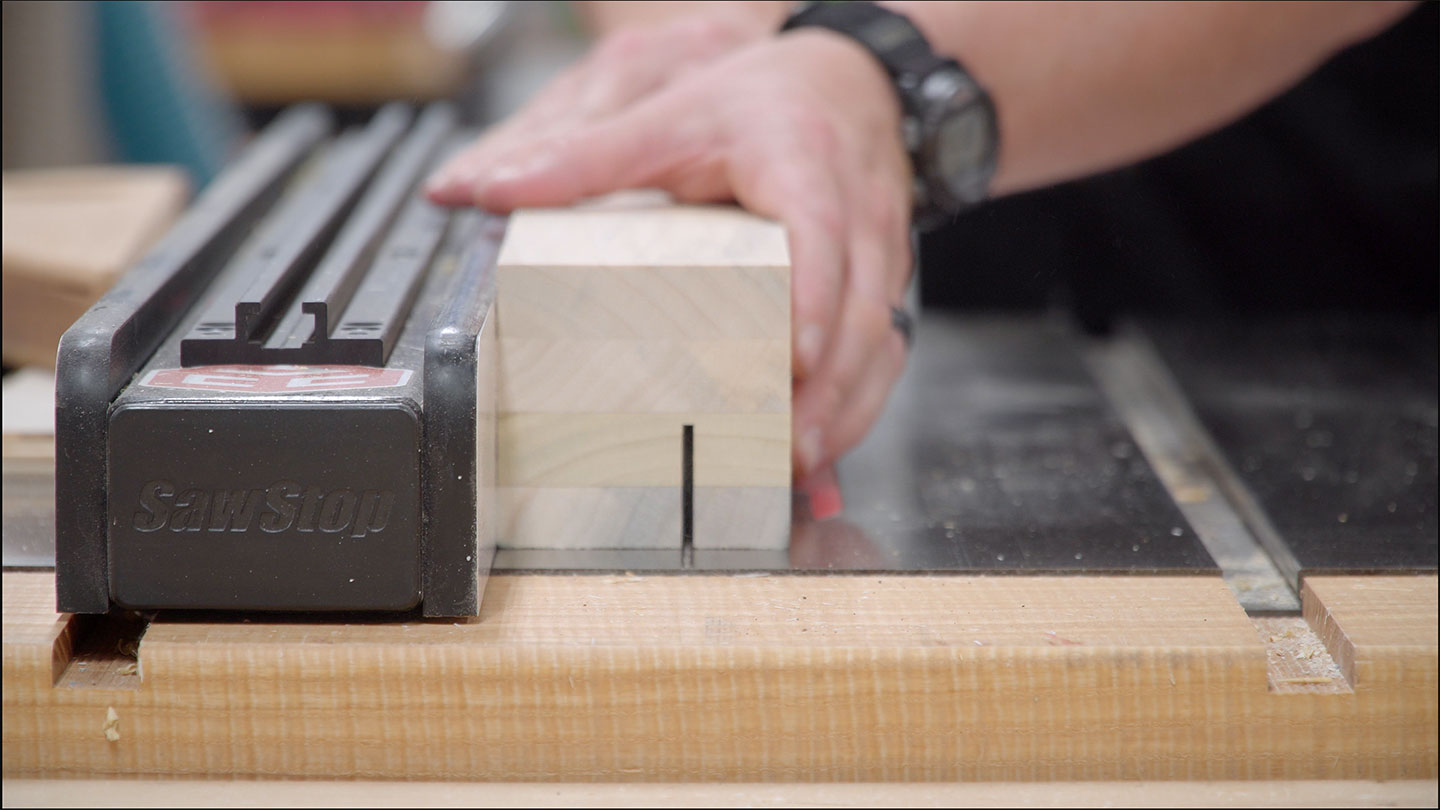

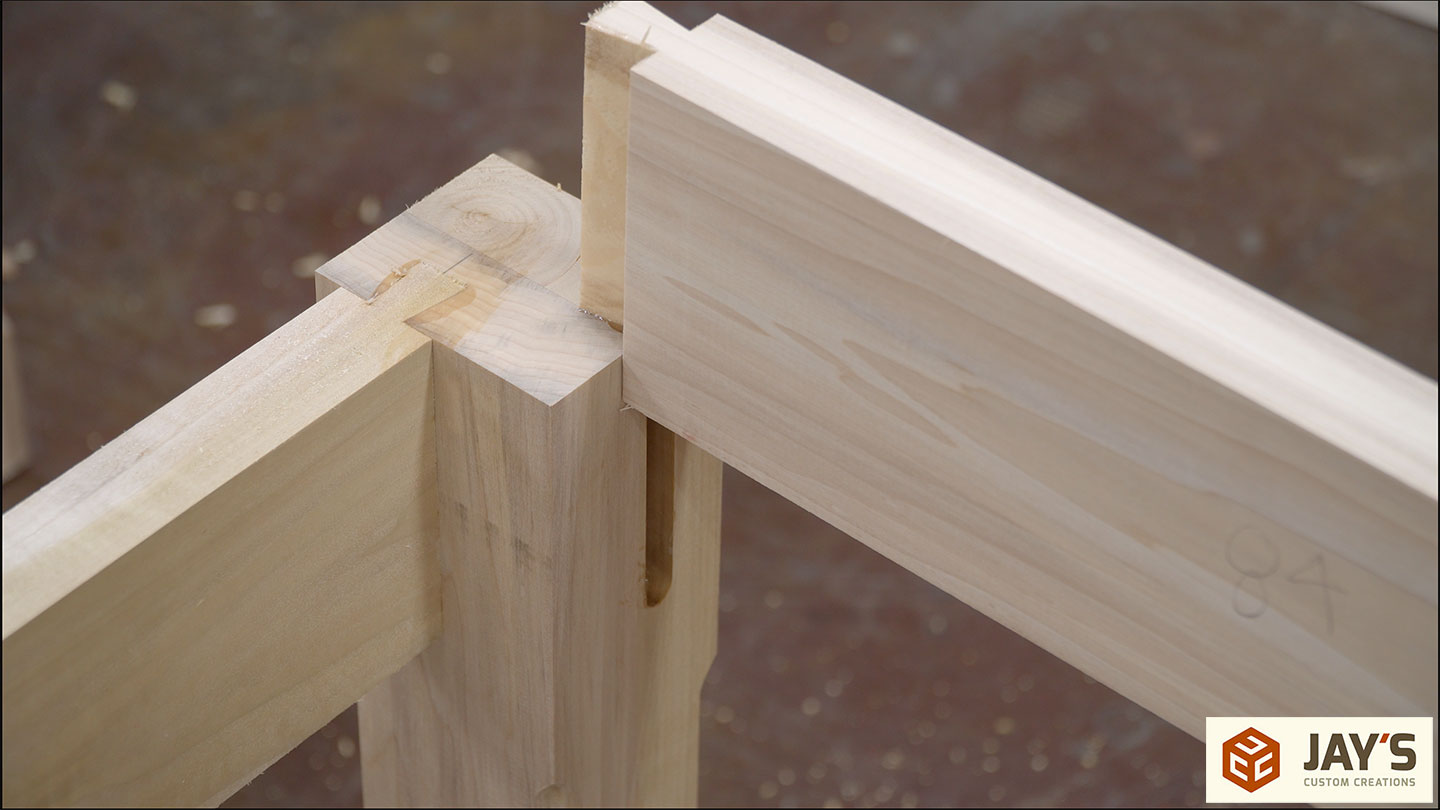

On the other hand, the desk noticed used to be handiest used for the nook leg rabbets. Those too will are compatible in position by the use of a rabbet. Two cuts on the desk noticed to create it however take into accout of the second one minimize I made. It’s generally no longer really useful to have the offcut trapped between the fence and the blade for kickback causes. If the piece has any pressure motion whilst being minimize you possibility that offcut being shot again like a missile. On this case, I didn’t see any indication of inner stresses and I extensively utilized a push stick with stay the offcut shifting ahead, previous the blade.

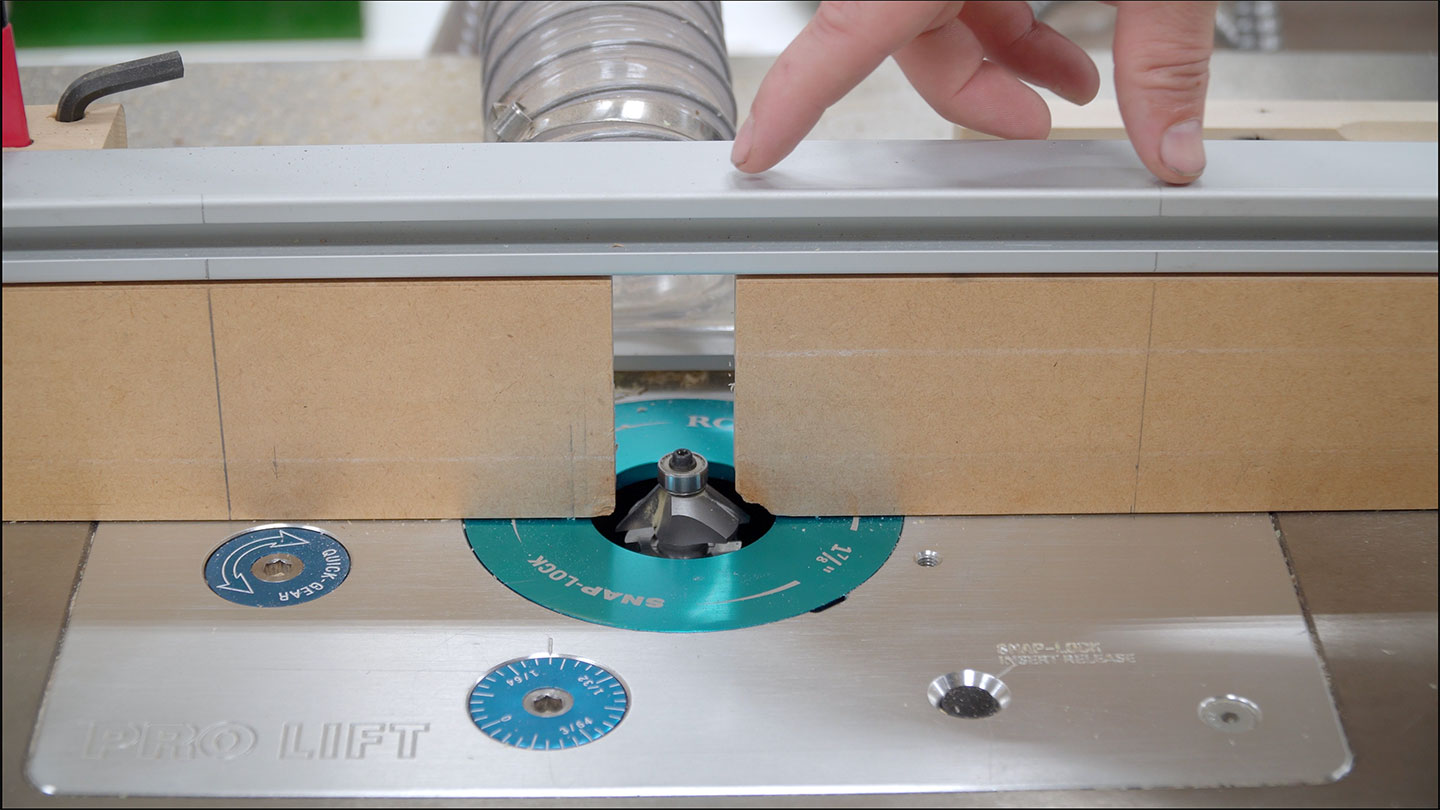

I’m the usage of the router desk so as to add a stopped chamfer element on every of the legs. The chamfer will get started and forestall a couple of inches clear of every finish of the leg so I scribed visible reference marks at the fence. It’s simple sufficient to begin and forestall at those traces through eye. No forestall block gadget is vital.

Throughout the chamfering procedure, I had an oopsie! The mud assortment at the router desk pulled some of the legs into the bit after I didn’t need it to. This gouge must be patched certainly one of two techniques. If this had been a transparent end piece I’d course a rabbet into the brink to totally get rid of the oopsie. Then glue a grain matching piece in position, flush it with each huge faces, then recreate the chamfer forestall location. Fortuitously, it is a painted piece so filling this with Bondo or one thing identical shall be more uncomplicated and simply as applicable.

The nook legs shall be secured with glue and a couple of screws in the course of the inside of the cupboard.

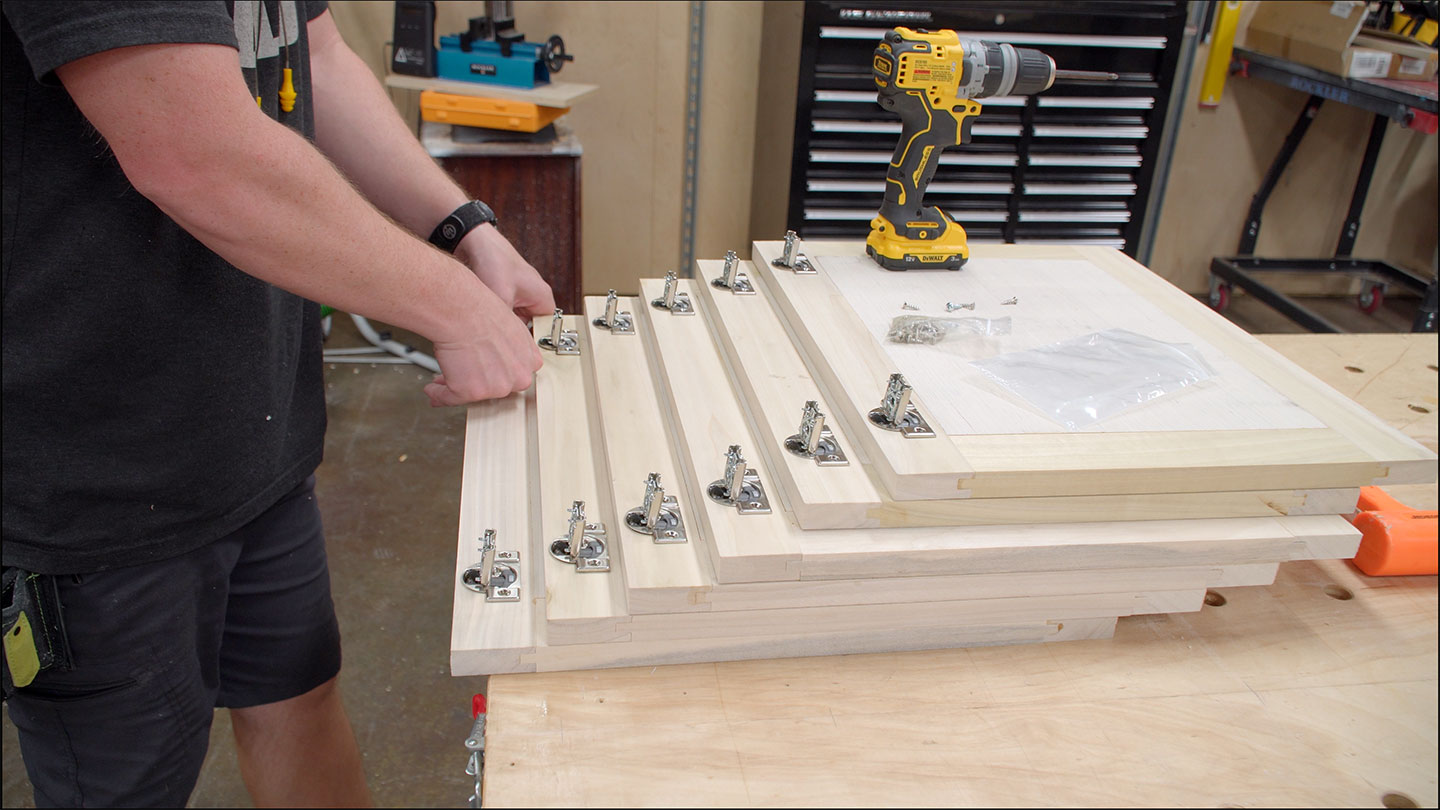

It’s time for the hinges. Those 1/2” overlay Blum comfortable shut hinges are my go-to for overlay doorways. They’re affordable and tremendous simple to enforce. I’m appearing this section on the drill press in the beginning as a result of that in point of fact is the quickest method to make the cup hinge holes.

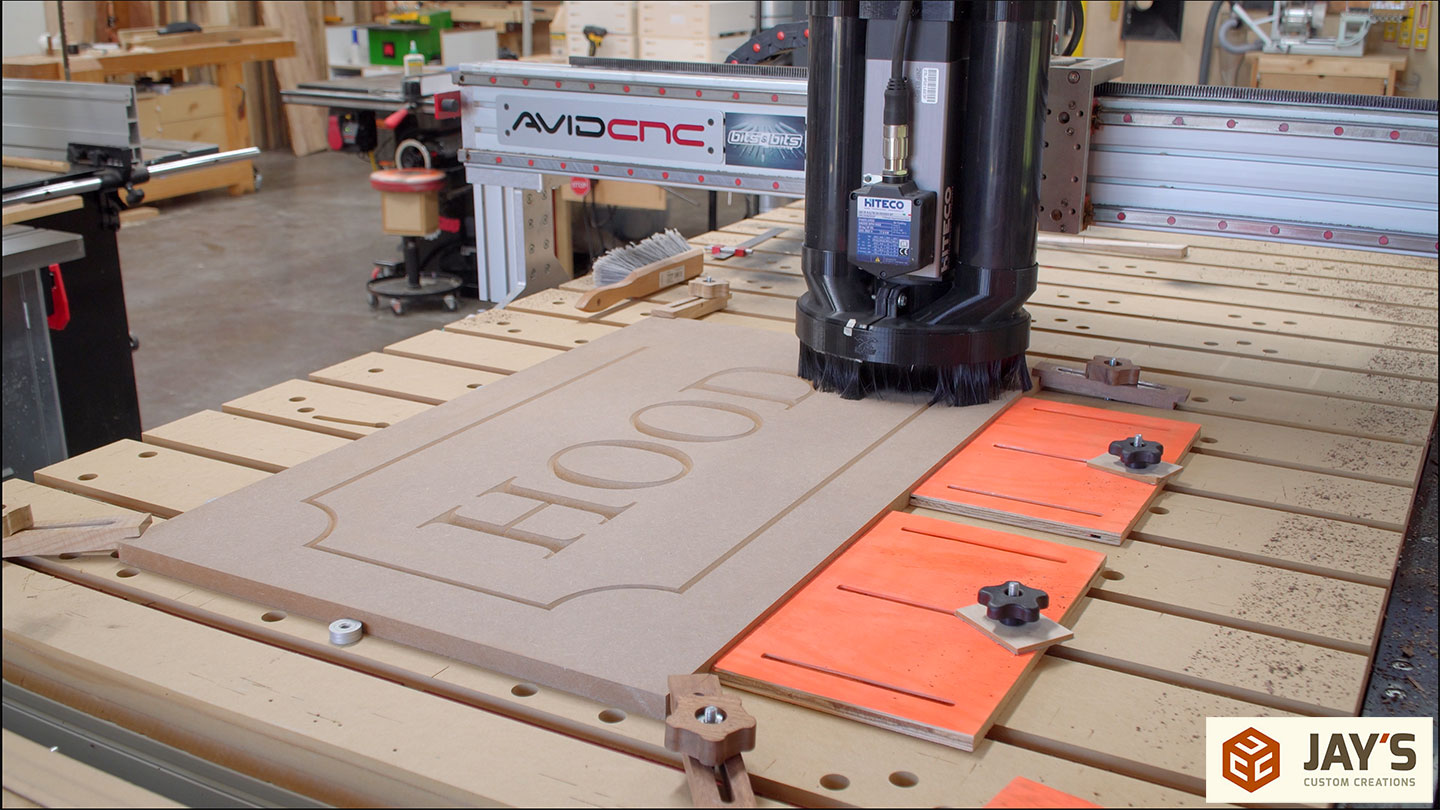

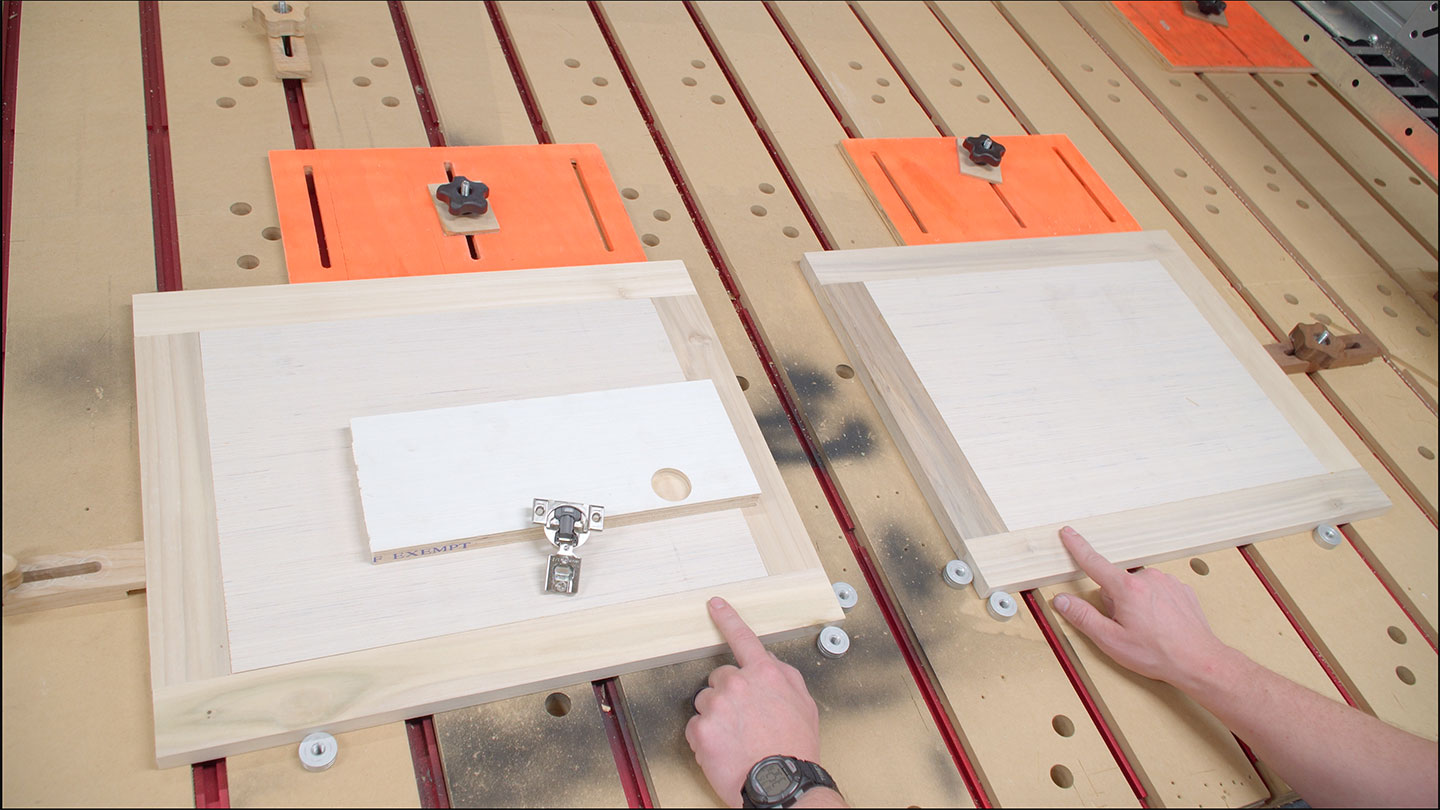

On the other hand, I couldn’t to find the right Forstner bit for the duty so I opted to make use of my CNC as an alternative. My setup is to just minimize one hinge hollow at a time. If I had been to create a program for each cup hinges I’d want a new program for every door of a special top. As a substitute, I made a program that has one hollow minimize on two doorways on the similar time. One is the highest hollow and the opposite is the ground hollow. By means of operating the minimize as soon as, switching the doorways, and operating the minimize a 2d time I’ll have all of my cup hinge holes minimize the similar distance clear of the highest and backside in the entire doorways irrespective of top.

Pop the hinges in position and upload the small screws to protected them. Relying at the picket species, pilot holes could also be required. Poplar is reasonably comfortable so I opted to not make the pilot holes.

One ultimate step sooner than putting in the doorways and drawer fronts is to flush the fringe. A hand aircraft in a workbench vise gets the task accomplished simply superb however I opted to make use of my belt sander. This is among the maximum used machines in my store that will get reasonably little airtime. It’s extremely at hand for lots of duties out of doors of woodworking as neatly.

The hinges used are 1/2” overlay hinges. Because of this when put in at the face frames they’re going to overlay the face body through 1/2” when closed. The one alignment wanted through the installer is to verify the peak is about for the highest and backside 1/2” overlay. One of the best ways to try this is with a forestall block clamped to the cupboard someplace. I generally put the forestall block at the backside in order that gravity works for your prefer. On the other hand, the space between the highest of the door and the ground of the drawer is what is going to be maximum noticeable so I opted to position the forestall block on most sensible. From right here, I will be able to use my foot to raise the door whilst I take advantage of my palms to carry the door and protected it with screws.

The drawer fronts are even more uncomplicated. The forestall block rests on most sensible of the doorways, pilot holes are drilled, and a couple of screws added from the interior of the drawer cling the drawer entrance in position. Those doorways and drawers will in the end get pulls that fit the countertop.

(*4*)

And that’s it for day 4 of development in this construct. All that’s left to do is somewhat little bit of fundamental trim paintings to the entrance and again plywood panels, the middle sink fortify, and the leveling ft. I’ll be completing the bottom with milk paint however will cling off on that till I am getting the matching farm desk constructed. That approach I will be able to spray them each on the similar time.

Wiping varnish is merely any logo of oil-based alkyd (common) varnish or oil-based polyurethane varnish in any sheen (gloss or satin) thinned about part with mineral spirits (paint thinner).

Wiping varnish is merely any logo of oil-based alkyd (common) varnish or oil-based polyurethane varnish in any sheen (gloss or satin) thinned about part with mineral spirits (paint thinner).