The next is excerpted from Bankruptcy 4 of “Make a Joint Stool from a Tree,” by Jennie Alexander and Peter Follansbee.

Joint stools are an enchanting piece of British and early American furnishings. Constituted of riven – no longer sawn – oak, their legs are normally became and angled. The aprons and stretchers are joined to the legs the use of drawbored mortise-and-tenon joints, no glue. And the seat is pegged to the body beneath. On account of those traits, the stools are a very good advent to the next abilities.

• Selecting the best equipment: Lots of the equipment of the seventeenth century are very similar to fashionable hand equipment – you simply want fewer of them. “Make a Joint Stool from a Tree” introduces you to the very elementary equipment you want to start out.

• Processing inexperienced oak: Cut up an oak the use of easy equipment, rive the bolts into usable inventory and dry it to a workable moisture content material.

• Joinery and mouldings: Discover ways to lower mortises and tenons by hand, together with the methods to verify a good are compatible on the shoulder of the joint. Make mouldings the use of shop-made scratch shares – no moulding planes required.

• Turning: Regardless that some joint stools have been adorned with easy chamfers and chisel-cut main points, many have been became. Be informed the handful of equipment and strikes you want to show period-appropriate main points.

• Drawboring: Joint stools are unusually sturdy articles of furnishings. Why? The drawbored mortise-and-tenon joint. This mechanical joint isn’t utilized in recent furnishings. Alexander and Follansbee carry the veil in this method and show the stairs to verify your joint stool will final 400 years or so.

• Completing: Many joint stools have been completed in the beginning with paint. You’ll be able to make your personal the use of pigments and linseed oil. The best end provides a translucent glow that no gallon of latex can ever supply.

Now we will go back to the framing portions, beginning with the stiles. Step one is to put out the mortises. We’ll define those steps separately as a result of it could possibly get complicated. We can name the mortises for the entrance and rear rails “instantly” mortises, the ones for the canted ends of the stool we can name “angled” mortises.

Stack the 4 stiles in combination, with their beveled within corners touching, and with radial faces up.

Those radial faces turn out to be the “entrance” and “again” faces of the stool. Take one stile, and paintings on its radial face.

To put out the stiles’ sq. blocks and the instantly mortises, it’s more uncomplicated to make use of what a wood worker now calls a “tale stick” this is marked with the stiles’ main points, somewhat than operating from paper drawings or patterns. This shop-made stick data the markings which are then transferred to the stile. We’ve got made those sticks to report other stools. The places and heights of the squared blocks, turning main points and positions of mortises can all be taken from the keep on with the stile. It’s best to mark ONE stile from the stick, then the opposite 3 stiles from that first stile.

Ensure the foot of the stile is trimmed sq.. Line up the foot of the tale stick and the ft of the stile. With an axe, mark the boundaries of the sq. blocks and scribe those marks throughout all 4 faces of the stile, with one exception – the highest of the stile is marked most effective at the radial face and the corresponding within tangential face (the place the instantly apron mortise is situated).

Now line the stick up at the within face and mark the places of the mortises in this tangential face.

Something to bear in mind is that the highest of the apron mortise isn’t on the identical top as the highest of the stile. This mortise drops down about 3/4″ from the stile’s best finish. Eyeball the highest of the apron mortise and scribe it with the axe and sq..

The next move is to mark the mortises with the mortise gauge. To set the gauge, make a mark along with your chisel’s edge perpendicular to, however proper in opposition to the stile’s arris. Subsequent, transfer over one chisel width and endure down exhausting sufficient to make a mark within the wooden. Then set the pins of your mortise gauge consistent with the site of this 2nd chisel mark. The result’s a mortise this is set in from the face of the inventory the thickness of the chisel. Our mortises are most often 5/16″, set in from the face 5/16″. This spacing is in accordance with research of era paintings; 5/16″ is sort of a usual from what we’ve observed.

The Angled Mortises

To seek out the site for the angled aspect mortises, use an adjustable bevel set to the required flare perspective. A slope of one:6 is what we’ve used on a number of stools. Our research of 17th-century stools display flare angles proper round that determine, some much less, none extra. To set the bevel, set a straightedge on a framing sq., positioning it at 1″ on one leg, and six″ at the different. Then regulate the bevel to this perspective and lock its nut to protected the environment. You’ll be able to then scribe this perspective on a work of wooden, and even scribe it at the wall. Just like the adjustable gauges, the bevel can lose its environment if bumped. Having the perspective scribed someplace makes it simple to reset it. Alexander became an adjustable bevel into a hard and fast one by threading a bolt via its inventory and blade.

To put out the aspect mortises, you should lift the road that designates the highest of the stool from the entrance radial face around the aspect tangential face. Set the bevel with its care for at the entrance face of the stile. Line it up with the marked best of the stool, with its angled blade pointing upwards at the different out of doors face of that stile. Scribe this line with the axe.

Then use a sq. to hold this line around the different within face. So the collection is sq., bevel, sq.. Take into account that it’s highest to hold the traces around the out of doors faces; the interior faces are unreliable. This structure is each easy and complex on the identical time. Occasionally it is helping to face the stile up and tilt it as it’ll be within the completed stool. Then you’ll simply visualize the place the angled mortises are and the way they stand up upper than the instantly mortises.

You’ll be able to repeat this procedure for the highest fringe of the stretchers’ mortises. Or you’ll mark this from the tale stick, this time lining up the highest of the stool with the scribed line that designates the highest of the aspect apron.

Now mark the mortises’ top and width on those faces of the stile. After you mark out two stiles, lay them aspect by aspect and test that they agree. A entrance or rear pair will have to have their radial faces matching, with the instantly mortises aiming at every different, and the aspect, angled mortises emerging up towards the highest of the stool.

Mortising

After you have struck the structure of the mortises, protected the stile at the benchtop close to its edge. Shove one finish of the stile in opposition to the bench hook then protected the stile with the holdfast.

Start mortising by maintaining the mortise chisel with the care for tilted clear of you, leaving its bevel with regards to plumb. Place the primary cuts with the mortise chisel about within the middle of the mortise’s period. A blow from the picket mallet drives the chisel downward. Flip the chisel round, and make every other chop aimed on the first. The result’s a V-shaped opening on the center of the mortise’s period. Trade the chisel’s place on this method, enlarging the V-shaped lower; the purpose is to achieve the intensity on the middle of the mortise as temporarily as imaginable. Then the remainder of the paintings is simply chopping down the top grain to elongate the mortise. As you get to the ends of the mortise, carry the chisel upright in order that its again floor is perpendicular to the stile’s floor.

There are a couple of stances and postures we use that build up the potency in mortising. For many of the paintings the chisel is pushed with a mallet, however once in a while hand drive comes in handy as neatly. When the use of hand drive, it is helping should you upward thrust onto the balls of your ft and are available down with your entire frame to force the chisel. Lean at the best of the chisel care for with the entrance of your shoulder to lend a hand force the device into the wooden. Then you’ll pry the waste up from the ground of the mortise. In fig. 4.12, the left hand is used to place the chisel, and the fitting hand and higher frame are using the device into the wooden.

It’s vital to stay the mortise chisel parallel to the face of the stile. You’ll be able to sight in opposition to a sq. situated at the benchtop. Power the chisel into the mortise, then step again and sight it in opposition to the blade of the sq.. With follow you’re going to learn how to sight this in opposition to the face of the stile, and no longer want the sq..

The moisture content material of the oak is essential at this level; most often it’s reasonably rainy within whilst you chop those joints. The inventory within the footage used to be planed rainy from the log not up to a month prior to chopping those joints. The straight-grained nature of the riven inventory makes mortising more uncomplicated than ever. The similar rules that practice to splitting practice right here as neatly. In impact the chisel is getting into the wooden at once on both the radial or tangential aircraft.

Chop the mortise to a intensity of about 1-1/2″. It’s very best to get that intensity on the center of the mortise; on the ends it calls for a bit of extra consideration. There’s a tendency to pry in opposition to the top grain of the mortise – this may bruise and warp the wooden there. Steer clear of the general ends of the mortise to start with, that method you’ll pry in opposition to the top grain that can finally end up as waste. End up by taking cuts instantly down the top grain with the again of the chisel perpendicular to the stile.

To get the final bits out on the backside of the mortise’s ends, chop instantly down into the ends, then flip the chisel round, and with the bevel down, force the chisel into the midst of the mortise, and are available towards the ends. Now carry up the chip at the again of the chisel.

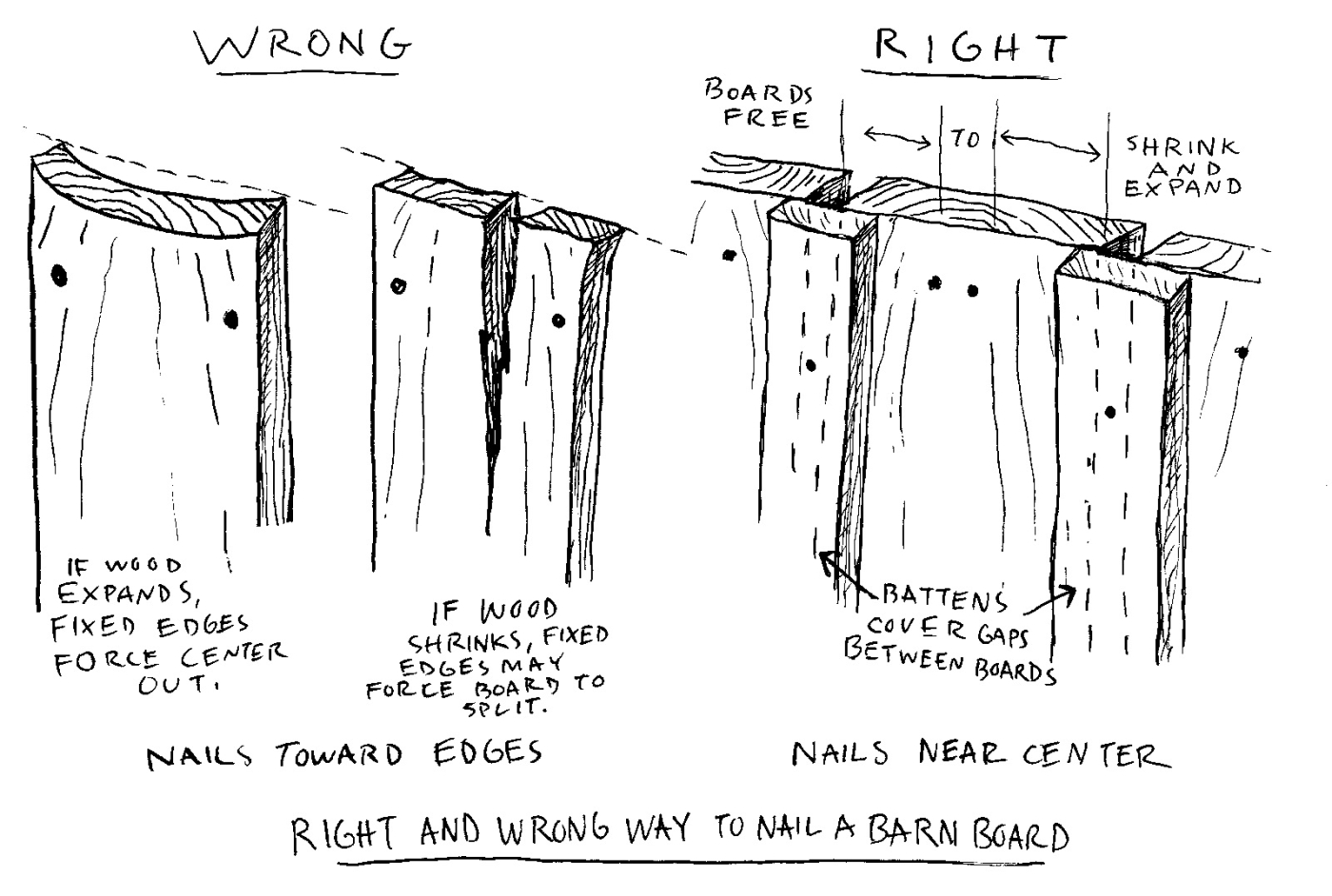

Beating it calls for realizing find out how to nail a board.

Beating it calls for realizing find out how to nail a board.